Sometimes the problem can seem to be a symptom too. The first step is to identify the problem. The fish-bone diagram can be created either by an individual or by a team of people. Break down the causes into sub-causes, till you cannot drill down further causes.Connect these causes to the category branches respectively. Analyze the causes from these categories that contribute to the effect.Identify the areas, broad level categories, to be studied and branch them from the backbone.Draw a straight line from the head, leading to the left.Draw the head on the right which contains the problem (effect or issue) for analysis.Kaoru Ishikawa, a Japanese professor and a quality management innovator of his time, used this tool for the first time when he worked with the Kawasaki shipyards in the quality management process.Ī few marketing industries use the categories as 7Ps: The sub-factors can be denote by similar small bones attach to the line indicating the category under consideration. When drawing up fishbone diagram, use these six categories to feed into the “spine” of your fish skeleton drawing. Environment: This includes anything outside the company’s control that may impact on results.Measurements: How is the process measure and monitor to evaluate quality?.Materials: The materials need to produce a quality product cannot ignore.

Machinery: Anything from the assembly line robots to tools or even computers.Methodologies: Consider the need for policies, rules, regulations, or procedures to ensure consistent quality.The possible causes of variation might be several but they will always fall into the following categories:įind ways to ensure that people involved in a process know what to do and when to do it. Six Sigma Master Black Belt Certification.For accelerating a process when traditional ways of problem solving take long time.To uncover bottlenecks and identify where and why a process does not work.A different point of view is a need to look on a problem.For identification of all potential root causes for an effect or a problem.To analyze a complex issue when there are multiple causes.Originally developed as a quality control tool, Ishikawa fishbone diagram may be helpful in the following activities: When people are unclear about what is causing an issue, ConceptDraw DIAGRAM can be helpful.

ISHIKAWA DIAGRAM CATEGORIES SOFTWARE

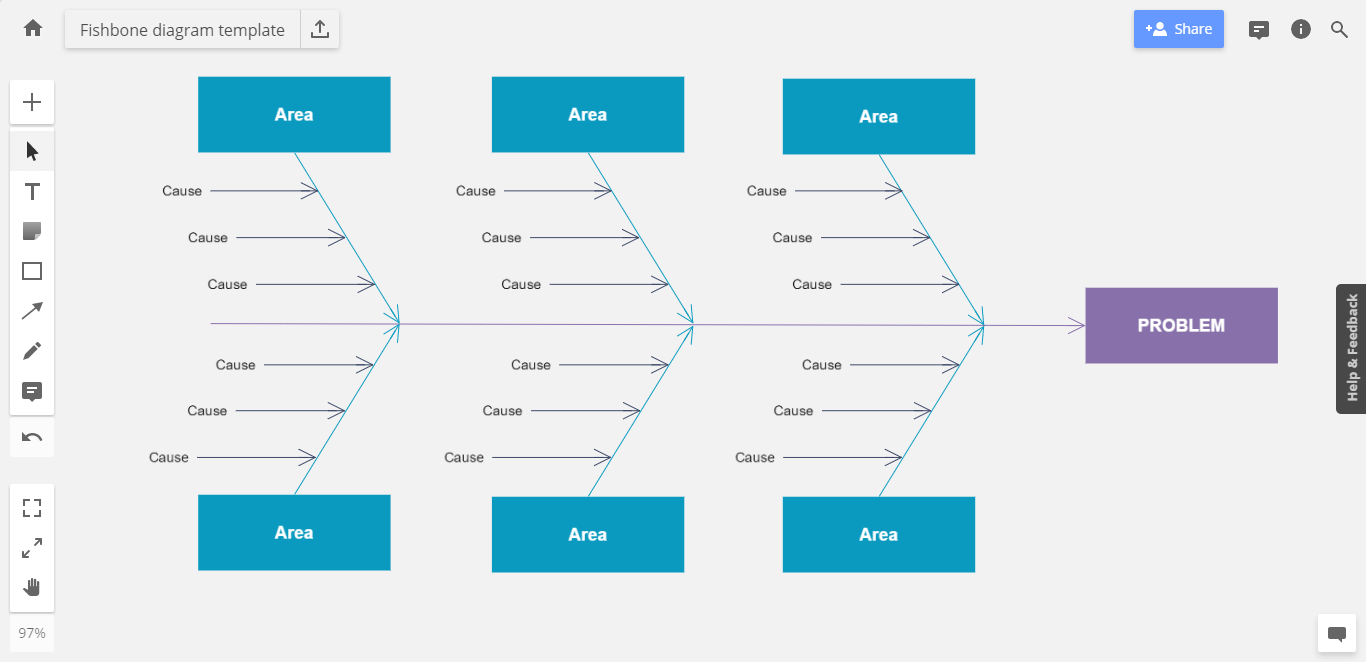

Professional diagramming software may help creating Fishbone (Cause and Effect or Ishikawa) diagrams. Ishikawa fishbone diagrams can be use by most of the entrepreneurs and almost any industry or person having a problem. The Ishikawa fishbone diagram strives to pinpoint everything that’s wrong with current market offerings so that you can develop an innovation that does not have these problems. The Ishikawa Fishbone diagram was develop by Kaoru Ishikawa during the 1960s as a way of measuring quality control processes in the shipbuilding industry. It shows where quality control issues might arise and determine which resources are require at specific times. It is a diagram that shows the causes of an event and is often use in manufacturing and product development to outline the different steps in a process. These are use in the “analyze” phase of Six Sigma’s DMAIC (define, measure, analyze, improve, control) approach to problem solving. Ishikawa fishbone diagrams are consider one of the seven basic quality tools. He credit for inventing the fishbone diagram for helping employees avoid solutions that address only the symptoms of a much larger problem. Kaoru Ishikawa was a Japanese quality control expert. Ishikawa fishbone diagrams are normally work right to left.Įach large “bone” of the fish branch out to include the smaller bones containing more details.ĭr. The design of diagram resembles skeleton of a fish. Once the team brainstorm all the possible reasons for a problem, the facilitator helps team rating the probable causes according to their level of importance and diagram a hierarchy. Is fishbone diagram effective in finding potential causes?įind our Upcoming Batches of Six Sigma Green Belt Certificate :- BatchĪdditionally, the diagram is helpful in troubleshooting processes and product development. How many types of fishbone diagrams are there?

0 kommentar(er)

0 kommentar(er)